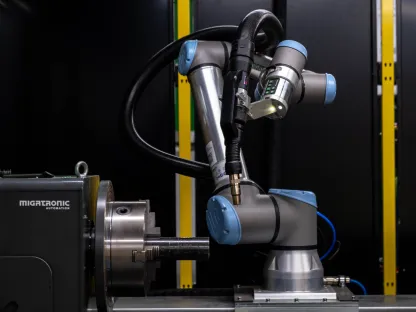

Welding: CoWelder Solutions

Energas offer a wide range of welding solutions to suit your operational needs. From manual welding through to full automation Energas has the solution to optimise your welding productivity. As a first step towards automation our CoWelder offer suits many metal fabricators needs for the applications below:

- Repetitive work

- Small series

- Downhand welding

- Fillet & overlap welds

- Welding jigs & fixtures

- Workpieces of limited size & weight

Cowelder, RADNOR™ Wire and ARCAL™ Force Bundle Offer | T Fillet Weld Compilation

Reducing risk

- CoWelders offer a safe working alternative to manual welding processes, reducing the risk to the workforce due to minimal interaction with the CoWelder workspace and welding operation.

- The risk of human workforce exposure to heat, fi re, electrical contact, fumes, etc is considerably

minimised when converting a suitable welding process from manual to CoWelding. - Multiple fume extraction options available to minimise welding fume risks.

Increasing productivity and efficiency while cutting costs

CoWelders give opportunities for enhancing or changing existing welding parameters to give increased and optimised productivity and consistent high quality over and above possibilities with manual welding:

- Travel speed

- Current Gas mixtures

- Wire Speed

- Voltage

Other benefits can include:

- Reduced consumables usage

- Improved gas to wire ratio

- Increased ‘arc on time’

- Consistently produces welds at the specified size, without over welding deviations.

Overwelding is one of the most significant wastes in welding. For example, if a 3/16” fillet weld is specified, but a 1/4” fillet weld is installed, that’s approximately 78% overwelding. 78% more gas, wire and labour. Semi automation such as CoWelders can eliminate this. This is all deliverable via having more consistency in the process compared to manual welding.

ARCAL™ Force is our most powerful, ready-to-weld solution for MAG welding of heavy carbon steel structures.

ARCAL™ Force was engineered with heavy use in mind. No matter the surface – oxidized or contaminated, gapped or mismatched – ARCAL™ Force is ready for your toughest and most challenging welding applications whether manual, semi or fully automated:

- Structural, automotive and general fabrication

- Heavy equipment - industrial, agricultural, construction and mining

- Containers

- Shipyards

Reliability: Product quality

- Ar-18% CO2 with controlled oxidation level.

- Compliant with ISO 14175-M21-ArC-18.

- Low level of H2O and N2 impurities.

Simplicity: All-purpose MAG welding of carbon steel

- All position welding.

- Highly tolerant: oxidized or contaminated surfaces, gaps or mismatches.

- Suitable for manual and automatic welding, solid or flux cored wire.

Designed for heavy applications

- Containers, earthmoving equipment, shipyards, etc.

Performance: Weld quality

- Mechanical properties secured with a large, rounded penetration weld shape.

- Excellent weld bead soundness (X-ray quality).

Savings and productivity

- Reduction of filler material consumption by low spatter emissions compared to gases with higher CO2 content.

RADNOR™ Precision™ SG2 G3Si Mild Steel MIG Wire

- Meets:

EN ISO 14341-A: G42 4 M21 3Si1

EN ISO 14341-A: G42 3 C1 3Si1

AWS A5.18: ER70S-6 - Shielding gas: EN ISO14175:2008 M21 (ARCAL™ Force)

- Butt and fillet welding of carbon steel sheet and plate

- Highly clean and uniform condition

- Superior wire surface finish for the best feedability and arc performance

- Optimal manufacturing process to precisely control chemical composition

- Can be used in all welding positions EN ISO 6947:PA/PB/PC/PD/PE/PF/PG

Case Study: Shand Engineering

Cobot Welding: Mastering Quality and Retaining Upskilled Welders

The problem for Shand Engineering was achieving a predictable, zero-defect weld required for components that cannot afford to leak into the ocean. This required a level of repeatability that exceeded what manual processes could consistently deliver across shifts and personnel.

Operations Manager Patrick Annibal explains the uncompromising nature of their market: "Everything is about traceability, making sure everything is absolutely right."

The solution had to solve two key needs simultaneously:

- Guaranteed Quality: Achieving and proving absolute consistency to satisfy industry regulators.

- Increased Capacity: Finding a way to speed up production without adding significant complexity, floor space, or labor.

The welding Cobot provided by Energas was the perfect answer. Its compact size and collaborative nature made it ideal for the SME shop floor. This welding cobot is immediately stepping in to handle the repetitive welding tasks that demanded unyielding precision.

Do you have any questions about our CoWelder + ARCAL™ Force + RADNOR™ Precision™ Wire bundle offer?

Please complete our contact form below and we'll come back to you as soon as possible.