What is Qlixbi? More than a gas bottle

Qlixbi is a gas cylinder package like no other.

Qlixbi is faster, more efficient and safer. Qlixbi answers the pain points welders have while working. Qlixbi also supports procurement and workshop managers by optimising processes and enabling their teams to work at their best.

- Qlixbi: After initial attachment your Qlixbi stays with you and your regulator.

- Qlixbi R: Instant click-on connectors have built-in regulators that save you time, effort and money. It makes welding easier and safer.

All the benefits of Qlixbi now available with ARCAL™ EN ISO14175:2008 compliant welding gases.

| Qlixbi Product | EN ISO 14175:2008 Category | Designation | Product Details |

|---|---|---|---|

| ARCAL™ Prime | I1 | I1-Ar | 100% Argon |

| ARCAL™ Speed | M12 | M12-ArC-2 | 92% Argon, 8% CO2 |

| ARCAL™ Force | M20 | M20-ArC-8 | 82% Argon, 18% CO2 |

| ARCAL™ Chrome | M21 | M21-ArC-18 | 98% Argon, 2% CO2 |

| ARCAL™ M24 | M24 | M24-ArCO-12/2 | 86% Argon, 12% CO2, 2% Oxygen |

| ARCAL™ M26 | M26 | M26-Ar-CO-20/2 | 78% Argon, 20% CO2, 2% Oxygen |

| ARCAL™ M14 | M14 | M14-ArCO-3/1 | 96% Argon, 3% CO2, 1% Oxygen |

Qlixbi product comparison to Energas standard welding gas solutions

| Qlixbi Product | EN ISO 14175:2008 Category | Designation | Product Details | Energas Standard Product Type & Package Type |

|---|---|---|---|---|

| ARCAL™ Prime | I1 | I1-Ar | 100% Argon | 300B HP ARG CYL Argon High purity 'W50' size Argon HP 'L50' Argon 4.8 L50 230B Argon HP Midi 20L |

| ARCAL™ Chrome | M12 | M12-ArC-2 | 98% Argon, 2% CO2 | Migweld-2 'W' size Migweld 2 'L47' |

| ARCAL™ Speed | M20 | M20-ArC-8 | 92% Argon, 8% CO2* | Migweld 8 'L47' Migweld 8 'W50' |

| ARCAL™ Force | M21 | M21-ArC-18 | 82% Argon, 18% CO2* | 300B MIG20 CYL Migweld 20 'W' size MIG 20 W50 230Bar Migweld 20 'L47' MIG 20 Midi 20L |

| ARCAL™ M24 | M24 | M24-ArCO-12/2 | 86% Argon, 12% CO2, 2% Oxygen | 300B MIG UNI CYL MIG UNI 'W' Size MIG UNI W50 230Bar Migweld Universal L 'L50' Migweld Universal 'L47' MIF UNI Midi 20L |

| ARCAL™ M26 | M26 | M26-Ar-CO-20/2 | 78% Argon, 20% CO2, 2% Oxygen | Migweld 22 'W' Size Migweld 22 Midi 'L20' Migweld 22 'L47' Migweld 22 'L50' |

| ARCAL™ M14 | M14 | M14-ArCO-3/1 | 96% Argon, 3% CO2, 1% Oxygen** | 300B MIG5 CYL Migweld 5 'L50' Migweld 5 'W' size MIG 5 W50 230Bar Migweld 5 'L47' Migweld 5 Midi 20 Ltd Migweld 5 Oxy Free 'W' 230B |

*ARCAL™ Force is 17% CO2 in Argon Vs Migweld 20 which is 20% CO2 in Argon

**ARCAL™ M14 is 3% CO2 1% Oxygen in Argon Vs Migweld 5 which is 5% CO2, 2% Oxygen in Argon

Qlixbi R with built in regulator

Qlixbi R instant click-on connectors have built-in regulators that save you time, effort and money. It makes welding easier and safer.

Key features of Qlixbi R

- HIgh performance built-in regulator delivers accuracy and stability

- Robust protective casing for gauges

- Quick setting knob for easy gas flow rate adjustment

- Instant click-on system no wrench required

- 360 rotation of connector reduces the risk of strains

- hi-vis on/off gas lever

Available in 33 and 50 Litre cylinders at 300 bar

With Qlixbi you can simply concentrate on your core task: welding. Qlixbi – Makes welder’s life easier. Check it out. You'll love it.

What makes welding with Qlixbi so revolutionary?

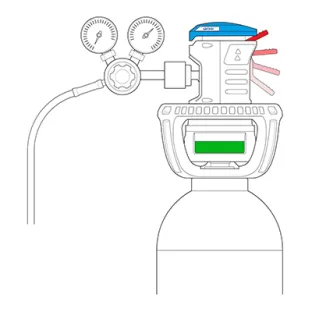

On/off lever

On/Off Lever reduces risk of gas leaks and leaving cylinder on overnight or weekends.

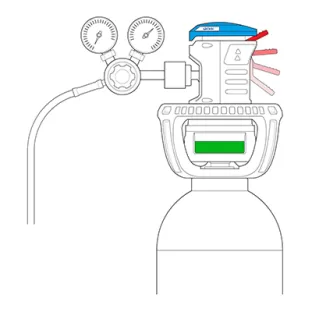

Hi-res gas reserve indicator

Hi-res gas reserve indicator goes red with 30 min's gas remaining. (Approx estimate of the welding time at the rate of 15L per minute with a 50L 230 bar cylinder, variable according to the welding working being carried out).

Robust and practical handling.

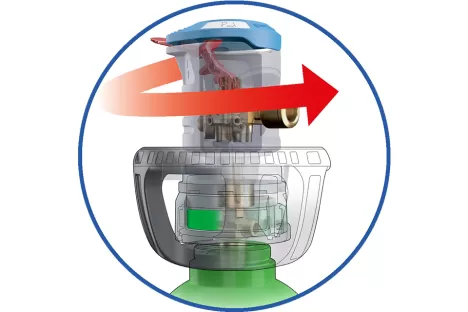

Look forward to robust and practical handling for your welding work. With Qlixbi you are on the safe side! You can change the bottle without the connector. The transport wheel can then be easily grasped and makes the bottle safe to roll. This means that no valve can open accidentally - no risk of a high-pressure leak.

And no matter how you change your working position: you simply rotate the Qlixbi connector with you - through 360°.

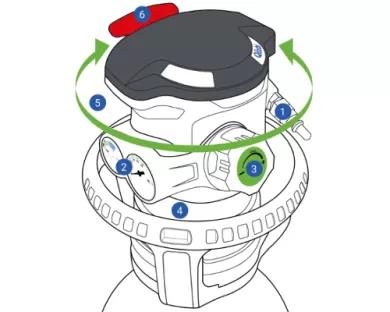

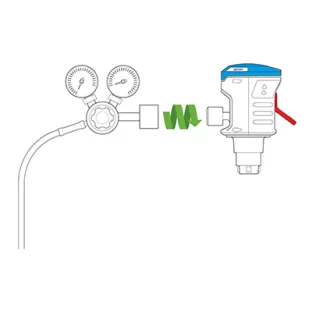

Connect with Qlixbi Classic in 5 easy steps

Attach your regulator

After initial attachment your Qlixbi stays with you and your regulator.

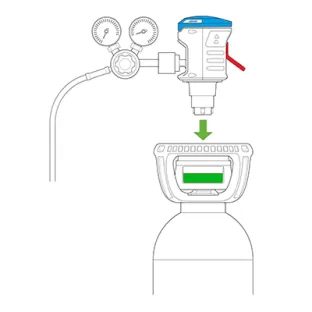

Couple the cylinder

Your Qlixbi clicks in to the cylinder. No spanner, no wrench required. Your Qlixbi rotates through 360o so you can position the regulator at any position.

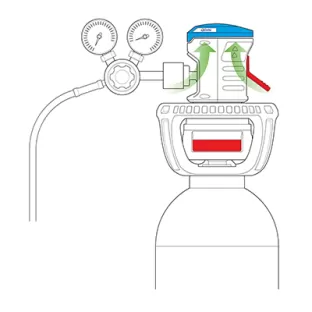

Turn the gas on

Lift the red lever up to open the gas flow. Use the regulator to manage the gas flow. That's it! You're ready to weld!

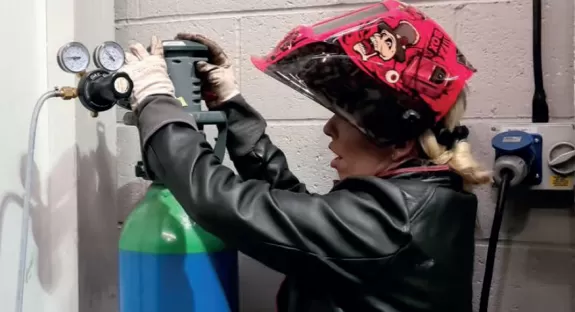

What do our customers say who work with Qlixbi?

Shand Engineering

Enhancing the Cobot cell was the Qlixbi gas system, which boosts both safety and efficiency. The system is easy for operators—it "just clicks into place". Its critical uptime feature means you can know in advance when you're running out of gas which eliminate the costly operational failure of running out halfway through a weld.

Patrick Annibal

Operations Manager

TWA Certifications Limited

“Here at TWA Certifications, Qlixbi has made a real difference in how our training school runs. Gone are the days of all day changing bottles and finding bottle spanners. Qlixbi has reduced the time to a few minutes rather than the 10 minute process we are all used to. As time is always short in any training environment as everyone is wanting your attention, Qlixbi’s unique click on connector has now allowed us to have more time with all of our learners. Not only are we saving time it ensures all bottle changes are easy, quick, safe and no leaks, no wastage. Qlixbi is having a big, positive impact in our environment and would recommend it to any other welding business.”

Kevin Birmingham

Director and Owner of TWA Certifications Limited

Norlec Sheet Metal

"Our welders are all very positive about the Qlixbi, not just about the click-on connector but also because of the hi-vis gas reserve indicator. Before we had Qlixbi, we didn’t use gas level indicators so the welder had no idea that he was about to run out of gas."

Technical guide & manual

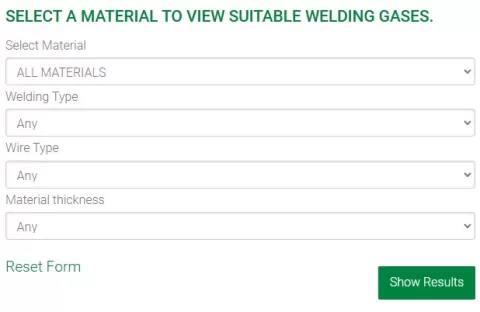

Welding gas selector guide

Helping you choose the right gas for your welding needs.

Select your material, welding type, wire type and material thickness and the tool which highlight our specific welding mixture suitable for your welding application.

Do you have any questions about Qlixbi?

Please complete our contact form below and we'll come back to you as soon as possible.

More information

ISO14175 compliant welding gases

Frequently Asked Questions:

How to choose which gas to use in MIG or MAG?

What is the difference between the MIG and MAG welding processes?

What is the difference between brazing and welding?

How to adjust the gas flow when welding?