RADNOR™ Precision™ & PEAK™ SG2 G3SI Mild Steel MIG Wire

RADNOR™ Precision™ is a copper-coated level layer wound solid wire that is well-suited for general GMAW welding applications. Provides excellent tolerance to rust and mill scale, improved wetting and bead shape characteristics in a highly fluid weld pool.

Available in 15kg plastic spools, 15kg metal basket spools and 250Kg drums.

We now also offer a copper free variant in RADNOR™ PEAK™ MIG welding wire, a copper free level layer wound solid wire that is well-suited for general GMAW (MIG/MAG) welding applications.

Meeting Standards:

- EN ISO 14341-A: G42 4 M21 3Si1

- EN ISO 14341-A: G42 3 C1 3Si1

- AWS A5.18: ER70S-6

- Butt and fillet welding of carbon steel sheet and plate

- Highly clean and uniform condition

- Superior wire surface finish for the best feedability and arc performance

- Optimal manufacturing process to precisely control chemical composition

- Can be used in all welding positions EN ISO 6957:PA/PB/PC/PD/PE/PF/PG

Recommended shielding gas to use with RADNOR™ Precision™ & PEAK™ SG2 G3Si MIG Wire

Shielding gas: EN ISO14175:2008 M21 ARCAL™ Force, (shown right with EXELTOP™, Qlixbi classic and Qlixbi R cylinder tops) C1

Typical Applications for RADNOR™ Precision™ & PEAK™SG2 G3Si mild steel MIG wire:

Chemical Composition of Wire (Wt. %) - Typical Wire (EN 13479):

| % C | % Mn | % Si | % S | % P | % Ni | % Cr | % Mo | % V | % CU | |

|---|---|---|---|---|---|---|---|---|---|---|

| Requirements | 0.06-0.014 | 1.3-1.6 | 0.70-1.0 | 0-0.025 | 0-0.025 | 0-0.15 | 0-0.15 | 0-0.15 | 0-0.03 | 0-0.35 |

| Typical Results | 0.08 | 1.50 | 0.89 | 0.012 | 0.013 | 0.03 | 0.02 | 0.002 | 0.003 | 0.11 |

| Typical Results (Copper Free) | 0.06 | 1.46 | 0.87 | 0.011 | 0.013 | 0.013 | 0.041 | 0.011 | 0.002 | 0.026 |

Ordering and packaging information:

| WIRE DIAMETER | 15KG PLASTIC SPOOL | 15KG METAL SPOOL | 250KG DRUM |

|---|---|---|---|

| 0.8mm | H710190 | H710193 | - |

| 1.0mm | H710191 | H710194 RAD54000040 (Copper Free) | H710196 |

| 1.2mm | H710192 | H710195 RAD54000041 (Copper Free) | H710197 |

Contact us today to see how RADNOR™ Precision™ & PEAK™ SG2 G3Si welding wire can enhance your welding operations.

NEW: Introducing RADNOR™ PEAK™ Plus Stainless Steel MIG wire & TIG rods

RADNOR™ PEAK™ Plus Stainless Steel MIG wire

Available for grades 308LSi, 309LSi and 316LSi in either 0.8mm, 1.0mm or 1.2mm metal basket reels.

- 308LSi Meets:

EN ISO 14343-A: G 19 9 LSi- Typical applications:

Suitable for welding AISI 302, 304 and 304L steel

- Typical applications:

- 309LSi Meets:

EN ISO 14343-A: G 23 12 LSi- Typical applications:

Used for welding dissimilar materials such as mild steel to stainless steel, as well as for a barrier layer in stainless overlay

- Typical applications:

- 316LSi Meets:

EN ISO 14343-A: G 19 12 3 LSi- Typical applications:

Ideal for welding chemical vessels, high pressure piping and tubing

- Typical applications:

(Please note using the 'buy online' button below, you will be redirected to our engweld welding equipment website to buy stainless steel mig wire online)

Ordering Information - Grades & Wire Diameters

RADNOR™ PEAK™ Plus Stainless Steel TIG Welding Rods

Available for grades 308L, 309L and 316L in either 1.6mm, 2.4mm & 3.2mm diameters.

- 308L Meets:

EN ISO 14343 A : W 19 9 L

Low carbon weld metal has lower carbon contents and provides

better corrosion resistance- Typical applications:

Suitable for welding 18%Cr-8%Ni steel ( AISI 304,304L)

and 19.5%Cr-10Ni steel (AISI 347)

- Typical applications:

- 309L Meets:

EN ISO 14343-A : W 23 12 L

Moderate ferrite content increases crack and corrosion resistance- Typical applications:

Used for welding dissimilar materials such as mild steel to stainless steel, as well as for a barrier layer in stainless overlay

- Typical applications:

- 316L Meets:

EN ISO 14343-A: W 19 12 3 L

Superior corrosion resistance to acetic acid, phosphoric acid,

acetate and phosphate due to additional Mo content- Typical applications:

Ideal for welding chemical vessels (AISI 316L) or 13% Cr or 18% Cr stainless steels without PWHT

- Typical applications:

(Please note using the 'buy online' button below, you will be redirected to our engweld welding equipment website to buy stainless steel tig rods online)

Ordering Information - Grades & Wire Diameters

Recommended shielding gas for RADNOR™ PEAK™ Plus Stainless steel MIG & TIG wire ranges

ARCAL™ Chrome

This product matches with chromium – the key component of steels for corrosion resistance. From household appliances to chemical vessels and pipes, for both austenitic and ferritic stainless steels, ARCAL™ Chrome offers brilliant welding performance.

Reliability: Product quality

• Ar-2% CO2 with controlled oxidation level.

• Compliant with ISO 14175-M12-ArC-2.

• Low level of H2O and N2 impurities.

NEW RADNOR™ PPE range now added

We've now extended the RADNOR™ product range to include a range of welders ppe & leatherwear including welders jackets, aprons, sleeves, mig gloves, tig gloves plus much more!

(Please note, you will be redirected to our engweld welding equipment website to purchase online)

NEW RADNOR™ Abrasives range now added

RADNOR™ abrasive discs are very cost effective, offering a longer lifespan and aggressive removal rates/cut speeds. Covering a range of applications such as Slitting, Cutting and Grinding with multiple benefits:

Key features:

• LONG LIFE, DURABLE discs

• EFFICIENT, aggressive removal rate

• SUPERIOR PERFORMANCE with improved usage times, fewer changeovers and less downtime

• EASILY IDENTIFIABLE with blue coloring

• PRICED RIGHT with significant savings vs. other OEM abrasives

• READILY AVAILABLE throughout Energas’ distribution network

(Please note, you will be redirected to our engweld welding equipment website to purchase online)

Do you have any questions or would you like a quote on RADNOR™ welding equipment and consumables?

Please complete our contact form below and we'll come back to you as soon as possible.

Related Pages

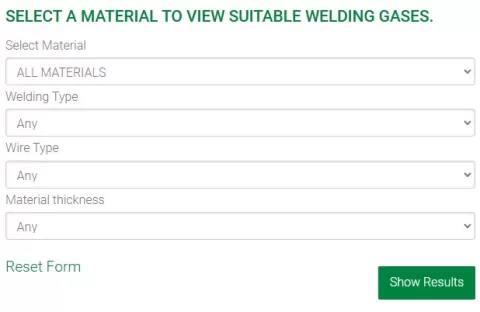

Welding gas selector guide

Helping you choose the right gas for your welding needs.

Select your material, welding type, wire type and material thickness and the tool which highlight our specific welding mixture suitable for your welding application.