Key Applications

Brazing

In brazing, air is used to assist in the heating process, particularly when oxy-acetylene or oxy-hydrogen torches are employed. In these applications, oxygen is mixed with air to increase the flame temperature, facilitating the joining of metals by melting a filler material without reaching the melting point of the base metals themselves. Air-powered equipment helps provide the necessary oxygen and pressure for efficient brazing.

Blasting

In industrial blasting, compressed air is commonly used to propel abrasive materials such as sand, steel shot, or other particles at high velocity to clean surfaces, etch materials, or remove coatings. Air-powered blasting systems offer precision, allowing for efficient material removal and surface preparation. In mining or construction, air may also be employed in rock blasting to create fractures, aiding in the extraction of minerals.

Die-casting

In die-casting, where molten metal is forced into molds to create precise metal parts, air is often used in cooling systems. Compressed air helps in controlling the temperature of molds and ensuring rapid cooling of cast parts to maintain quality and dimensional accuracy. Air may also be employed to blow excess material from molds or to clean parts after the casting process.

Respiration Equipment

In medical and respiratory applications, air is essential for various life-support and breathing equipment. Compressed air is used in ventilators, anesthesia machines, and breathing masks to deliver oxygen to patients, particularly those in critical care, emergency situations, or undergoing surgery. Additionally, air is used in scuba diving tanks to provide breathable air for divers at varying depths.

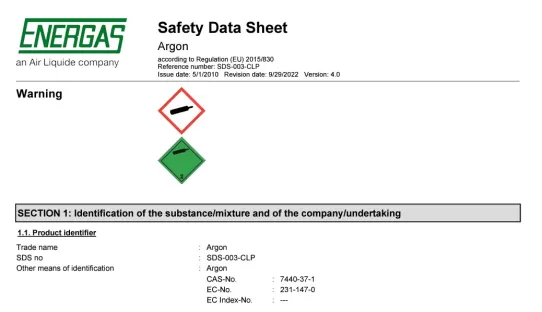

Find your safety data sheet

Safety Documentation

Gas safety data sheets (MSDS)

Find the reference document you need.

Find your local Energas branch or Agent

Do you have any questions about Air gas?

Please complete our contact form below and we'll come back to you as soon as possible.