Benefits

Stable & consistent mixtres

- Fixed composition: no calibration on-site required

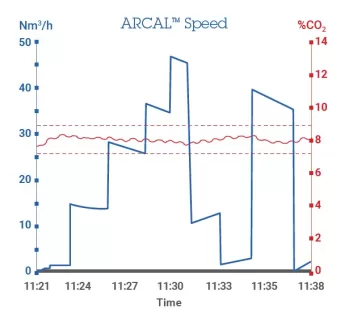

- No deviation of the composition whatever your flow rate

- No need of an analyzer

Adaptable equipment

- Standard units available:

- Mono-mix with one fixed gas composition

- Dual-mix with two outputs of different fixed gas compositions

- 50 m3/h and 100 m3/h max flow rate

- Units can be combined to refine your needs

Designed for ARCAL™

Premium mixtures for weding

Compliant with EN ISO14175:2008 Welding Consumables

- Gases and gas mixtures for fusion welding and allied processes as the key standard for reference for the production of welding gases for the UK market.

Available for all ARCAL™ reference mixtures:

ARCAL™ Chrome M12-ArC-2

ARCAL™ Speed M20-ArC-8

ARCAL™ Force M21-ArC-18

Also available for a list of technical products:

- ARCAL™ M14..................M14-ArCO-3/1

- ARCAL™ M23..................M23-ArCO-5/4

- ARCAL™ M24..................M24-ArCO-12/2

- ARCAL™ M26..................M26-ArCO-20/2

- ARCAL™ M13..................M13-ArO-2

- ARCAL™ He20................I3-ArHe-20

| Type | Status | Application |

|---|---|---|

| WA | Non-Standard | Gas Combination Ar-He |

| WB | Non-Standard | Gas Combination |

| WC | Non-Standard | Gas Combination |

| WD | Non-Standard | Gas Combination |

| WE | Standard | ARCAL™ R1-2, ARCAL™ R1-5 |

| WF | Standard | ARCAL™ Chrome, ARCAL™ Force, ARCAL™ Speed, ARCAL™ M13, ARCAL™ M14, ARCAL™ M23, ARCAL™ M24, ARCAL™ He20 |

| WG | Standard | Gas Combinations N2-O2 |

| WI-I | Non-Standard | Gas Combinations Ar-O2 Ar-CO2-O2 |

| WJ | Non-Standard | Gas Combination Ar-N2 |

| WK | Non-Standard | Gas Combination N2O2 |

| WS | Non-Standard | Gas Combination Ar-CO2 |

Benefit from Air Liquide expertise with welding gas supply

Quality of liquid products:

• A strict control of raw products notably with ARCAL™ Prime for Argon and our high quality CO2

• The Air Liquide solution with pure gases in liquid and or bundle supply combined with the dynamic on-site mixer ensures the same quality as premixed welding gas cylinders

World class logistics:

• Compliant with the most stringent safety standards

• Flexibility and reliability of your welding gas supply via liquid and or cylinder bundle combinations for a high quality on site mixing solution

• Compatible with all types of storage tanks, including Skid Tanks

Cylinder manifolds and bundles for onsite mixing

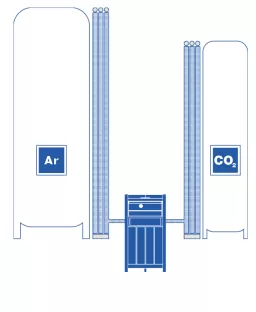

Mix and match options using bulk tanks, skid tanks and cylinder packs to suit your overall welding gas mixture volume needs:

For 2 part mixtures:

• CO2 N2, O2, H2 or Helium cylinder packs to combine with Argon tanks

For 3 part mixtures:

CO2 and or O2 skid tank or CO2 and or O2, He and or O2 cylinder manifold/ packs to combine with Argon tanks

Focus on your welding performance

-

Get accurate gas mixtures

Whatever your consumption, whatever your flow rate, the Dynamic On-site Mixer delivers a consistent welding gas from liquid and or cylinder bundle or manifold supply. -

Get the highest reliability

A smart robust design that requires no power supply, no solenoid valve, no buffer tank.

Do you have any questions about the dynamic on-site mixer?

Please complete our contact form below and we'll come back to you as soon as possible.