Helping you to find real savings, improve welding productivity and monitor your progress

Are you operating your welding processes at your optimum?

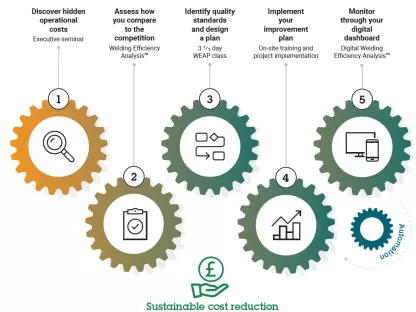

The preview of what you can learn about your operation from a Welding Efficiency Analysis as well as how your operation compares to the industry average.

WEAP provides you with insight into how your operation is performing and helps you quantify the real costs of any inefficiencies you may have. We can analyse your operation to help you evaluate cost to weld, travel speed, over welding, gas to wire ratio, MIG consumable efficiencies, plasma consumables efficiencies, operator factor and much more.

As a business owner or manager responsible for delivering quality to your customers while managing your bottom line, you have to consider all of the variables:

- Is your process as efficient as it could be?

- Are you producing the quality that your customers expect?

- Is there an opportunity to produce more and spend less on welding costs?

Answering these questions with certainty will help you ensure your operation continues to succeed by assuring your customers receive a quality product while controlling your production costs.

What are your challenges?

-

Benchmarking my performance against industry averages

-

Need to set quality standards for my fabrication shop

-

Finding sustainable cost savings for my business

How can Energas help?

-

Using data from 2,500+ customer case studies, we show you how you compare to industry averages and find improvement opportunities

-

The Welding Efficiency Analysis Program helps you develop quality standards, design a plan and implement it with your team

-

Our systematic approach takes a complete look at your operating expenses and procedures to find areas where you can drive your costs

Energas can help you develop a continuous improvement plan that generates savings

Our Fabrication Excellence experts are focused on helping you optimise your welding operations to compete efficiently and effectively in the marketplace. With support from Airgas and Air Liquide we have access to studies on more than 2,500 welding operations and developed the Welding Efficiency Analysis Program.

From start to finish, we’ll work with you to develop and implement a plan for quality assurance that generates sustainable savings for your business. In addition, we help you remain focused on your goals with a digital monitoring tool and reports that allows you to track your progress over time.

Do you have any questions about our Welding Efficiency Analysis Program (WEAP)?

Please complete our contact form below and we'll come back to you as soon as possible.

More information

ISO14175 compliant welding gases

Frequently Asked Questions:

How to choose which gas to use in MIG or MAG?

What is the difference between the MIG and MAG welding processes?

What is the difference between brazing and welding?

How to adjust the gas flow when welding?