Solutions for every use

Welding in a nutshell

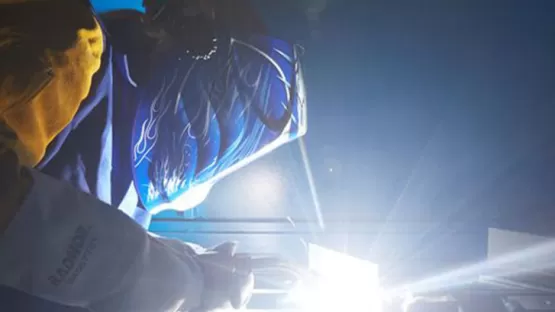

Arc welding is the most common method. The energy is brought through an electric arc (and currents up to several hundred amperes).

This process requires the use of a gas

- Usually an argon-based mixture

- To protect the liquid bath from ambient air. The devices can be adapted to increase productivity in automatic or robotic welding.

Whether active or inert, welding gas is always indispensable in arc welding processes. It provides localized protection of the weld essential to achieve the mechanical properties of the joints and it allows to optimize the speed and/or the quality of welding, depending on the project. The choice of gas mixture used is therefore far from trivial!

Under the term “gas flow arc welding”, several different types of processes are hidden. Each has its own characteristics… and requires specific welding gases!

Gases adapted to each welding situation

- Arc welding: There are different processes, which all use the same physical principle: the rise in temperature created by an electric arc. Each process has its own strenegths: productivity, quality, flexibility according to needs.

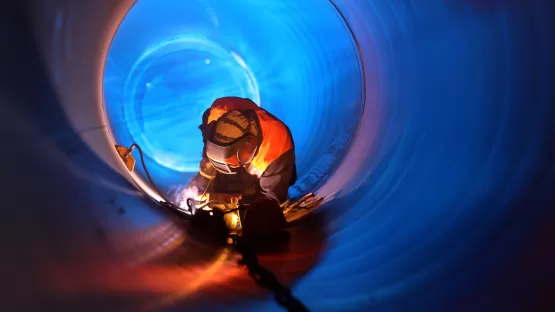

- TIG welding: TIG welding is an arc welding process that uses a non-fusible tungsten electrode (hence the name Tungsten Inert Gas). TIG welding creates an electric arc between the electrode (built into the torch) and the work piece, protected by an inert gas. For example, TIG is used in orbital welding of pipes.

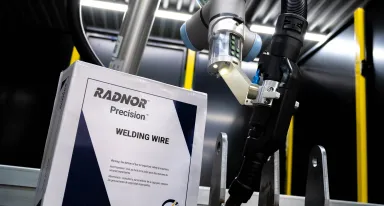

- MIG and MAG welding: MIG stands for Metal Inert Gas and MAG for Metal Active Gas. The two processes differ in that in MIG welding the gas is inert (and thus does not react with the molten metal) while in MAG welding it is active. MIG/MAG welding is a so-called semi-automatic process: the fusion of the metal of the part to be welded is obtained by an electric arc that is created between a welding wire and the parts to be assembled. This fusible electrode welding wire therefore also serves as filler metal. Usually solid wires are used, but flux-colored wires are also available. MIG/MAG welding machines are supplied with a wire feed system to control the wire feed speed during welding.

The electricity for the torch is fed to the wire through a copper contact tube. Recent MIG/MAG welding generators contain electronic systems for controlling the parameters and allow simplified operation. In practice, with a simple trigger on the torch, you can call up programs to adapt to different positions, e.g. flat, vertically up, etc.

Our experience at your service

Thanks to its long experience in the metal fabrication industry, Energas has developed specialised gases and services for different types of applications (welding, cutting, and heating).

Our services, equipment and gases ARCAL™ (TIG, MIG, MAG and Plasma arc welding) and LASAL™ (laser welding-cutting), developed by our experts, meet the most demanding needs of the metal fabrication industry.

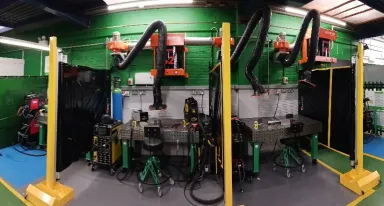

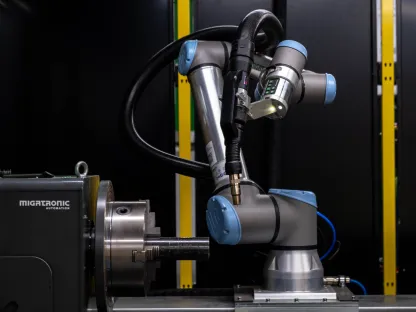

Welding: CoWelder Solutions

Energas offer a wide range of welding solutions to suit your operational needs. From manual welding through to full automation Energas has the solution to optimise your welding productivity. As a first step towards automation our CoWelder offer suits many metal fabricators needs for the applications below:

- Repetitive work

- Small series

- Downhand welding

- Fillet & overlap welds

- Welding jigs & fixtures

- Workpieces of limited size & weight

Modes of Supply

Welding Expertise & Support

Case Study: Shand Engineering Ltd

The problem for Shand Engineering was achieving a predictable, zero-defect weld required for components that cannot afford to leak into the ocean. This required a level of repeatability that exceeded what manual processes could consistently deliver across shifts and personnel.

Operations Manager Patrick Annibal explains the uncompromising nature of their market: "Everything is about traceability, making sure everything is absolutely right."

The solution had to solve two key needs simultaneously:

- Guaranteed Quality: Achieving and proving absolute consistency to satisfy industry regulators.

- Increased Capacity: Finding a way to speed up production without adding significant complexity, floor space, or labour.

The welding Cobot provided by Energas was the perfect answer. Its compact size and collaborative nature made it ideal for the SME shop floor. This welding cobot is immediately stepping in to handle the repetitive welding tasks that demanded unyielding precision.

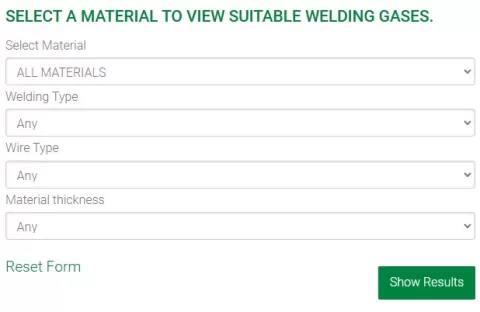

Welding gas selector guide

Helping you choose the right gas for your welding needs.

Select your material, welding type, wire type and material thickness and the tool which highlight our specific welding mixture suitable for your welding application.

Do you have any questions about welding gas or welding equipment?

Please complete our contact form below and we will get back to you as soon as possible.

Latest news articles

Types of welding gases

Welding gases are used in various welding processes to protect the weld area from atmospheric contamination, control the temperature, and aid in the formation of a strong , durable weld joint. The choice of welding gas will depend on the welding process and the type of metal being welded e.g. carbon steel, stainless steel, and aluminium and alloys. You may also need to consider the desired weld characteristics and the equipment available.

There are different categories of gases used in welding. Each category serves specific purposes and has unique properties.

Shielding Gases are primarily used in welding to protect the weld arc from atmospheric contamination. They create a stable environment around the weld pool to prevent oxidation and other undesirable reactions during the welding process.

Shielding gases are used in TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), and MAG (Metal Active Gas) welding processes.

Inert Gases are a subset of shielding gases that do not chemically react with metals or other materials. They create a non-reactive atmosphere to prevent oxidation and contamination during welding.

Inert gases are commonly used in TIG welding to weld non-ferrous metals like aluminium, titanium, and stainless steel.

Speciality Gases are used in specific, often specialised applications that require unique properties. They may not be inert or used for shielding but are essential for specific industrial processes.

Common welding gases

Argon (Ar): Argon is commonly used as an inert shielding gas in TIG welding, particularly for welding non-ferrous metals like aluminium, titanium, and stainless steel.

Helium (He): Helium is often used in combination with other gases for TIG welding, especially for materials that require a hotter and more penetrating arc, such as aluminium and copper.

Carbon Dioxide (CO2): CO2 is an active gas and is frequently used in MAG welding, particularly for carbon steel and some low-alloy steel applications.

Oxygen (O2): Oxygen is an active gas and occasionally added to shielding gases for MAG welding processes to improve weld pool fluidity and penetration, mainly when welding carbon steel and mild steel.

Nitrogen (N2): Nitrogen may be added to shielding gases to improve arc stability and reduce porosity when welding stainless steel and other non-ferrous metals.

Acetylene (C2H2): Acetylene is primarily used in oxy-fuel welding and cutting processes, providing a high-temperature flame for cutting and welding metals.

Argon-CO2 Mixtures: Mixtures of Argon and CO2 are commonly used in MAG welding, providing a balance between penetration and reduced spatter, often used in carbon steel.

Argon-Helium Mixtures: These mixtures are used for TIG welding when a hotter arc is needed, typically for thicker materials and high-speed welding.

More information

ISO14175 compliant welding gases

Frequently Asked Questions:

How to choose which gas to use in MIG or MAG?

What is the difference between the MIG and MAG welding processes?

What is the difference between brazing and welding?

How to adjust the gas flow when welding?